A manual bilge pump is a vital component for any recreational sailboat. None of us can predict if and when an electric bilge pump may fail, so having a reliable manual backup pump makes sense for anyone heading out for a sail, short or long.

Many boats rely on the Gusher 10, from Whale Pumps. Based in England, Whale Pumps provide a range of different pumps. While some of Gusher’s pumps are plastic, the common Mark 10 is made from aluminum, which can corrode when in contact with salt water for an extended period.

When I purchased my sailboat, I found that the manual bilge pump in the cockpit did not work. Knowing I had water in the bilge, I could work the handle, but nothing would reach the pump or exit the boat.

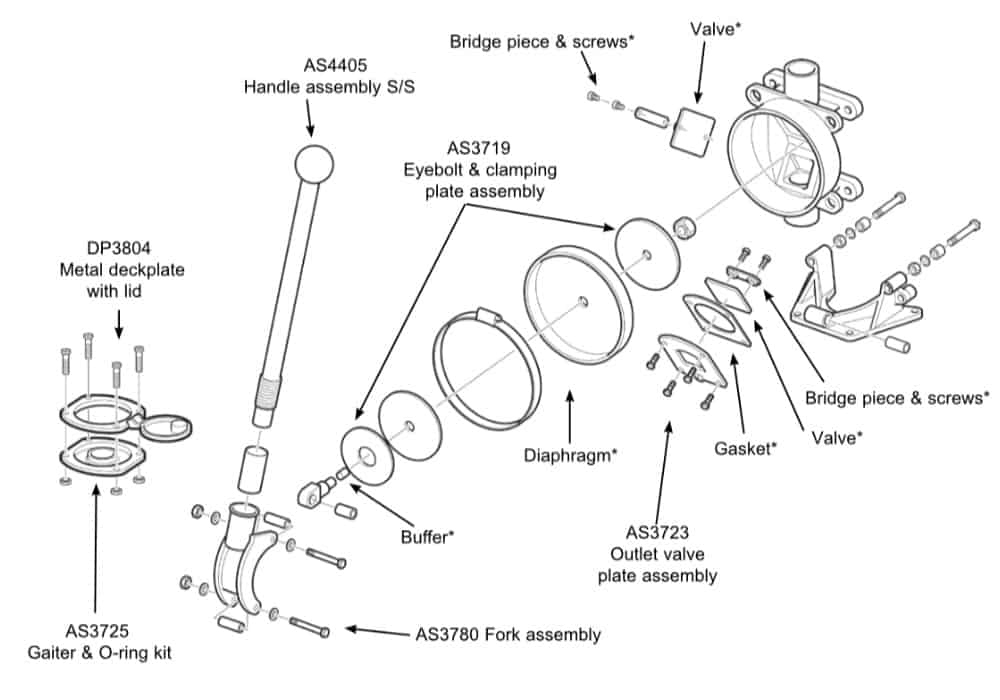

The pump functions by lifting and lowering a diaphragm. Pulling up on the diaphragm with the handle draws water into the body of the pump through the inlet flapper. Here’s what the pump looks like disassembled:

Substantial corrosion of the aluminum is present. I discovered after opening (by virtue of a different shade of yellow spray paint inside) that a previous owner had experienced the same problem and tried to repair it.

There are at least two sets of parts that you can buy to repair your Gusher 10 pump. One is a set of the ‘Pump Service Kit’ with bellows and internal flaps that let water in and out of the pump. You can find such a set on-line.

I ordered this set, but I realized that my pump’s failure was due not to the flaps, but to the corrosion of the square metal plate to which the outlet flap attaches. Fortunately, this part can also be replaced independent of the rest of the pump. The part number for the outlet valve plate is Whale Pumps AS3723. I found mine on ebay, but googling that part number will likely yield you an independent marine supplier who has one.

Here is a full cut-away of the pump with all of the part numbers:

I scrubbed out the loose corrosion inside the body of the pump and painted it with Rust-Oleum Semi-Gloss. I installed the new Outlet Valve Plate Assembly and this is how it turned out:

The most frustrating part of the project is/was getting the pump disconnected from within the cockpit and then getting the inlet and outlet hoses clamped securely enough so that the pump can function.It’s not a sexy job, but easy to do once you have the pump pulled out of the boat, and important for peace of mind and a safe trip.

One last aside is that some sailors decide to deal with this corrosion issue differently by replacing the Gusher 10 with another very similar Whale Pump product that is plastic-bodied, the Titan. It would be ideal if the mounting holes for the Titan and Gusher 10 were identical, but I am told they are not.

Did I forget anything? Any other suggestions? Please let me know in the comments section.