I’m replacing the standing rigging on my boat, and at a local workshop/seminar put on by a local sailing group with a presentation from a rigger, I became interested in the idea of synthetic (rope) rigging instead of wire. I presented some ideas for discussion in post on the Ericson forum.

I vacillated, but after hearing from a couple of informed parties, decided to order the synthetic rigging instead of wire from Colligo Marine.

The basic challenge at the outset is for the boat owner or rigger to communicate to Colligo exactly what they need to build for you.

There is an order form. Mine looked like this:

With specific measurement for each stay/shroud:

The values in the grid are provided by the person ordering. The Colligo web site suggests they prefer to take measurements for the rigging lengths while the existing rig is still in place on the boat and tuned. Maybe for a pro rigger. There’s no way I (as a novice DIY guy) would have done a decent job of this (trying to run a long tape along the upper shroud from the tip of the mast to the chainplate? The flapping of the tape in the wind alone would introduce substantial measurement deviation.

Fortunately, I was taking on this project while the mast was out of my boat. I brought the shrouds home and laid them out on my sidewalk. It’s definitely a measure-three-times, write-once kind of a situation. Some comedy with trying to keep the tape flat and parallel to the wire, in the wind. Not giving any litigious neighbors a reason to trip and fall, etc..

In addition to these long measurements, one has to provide fairly careful small tolerance measures of the different termination points and the cable itself.

John Franta runs Colligo. I had a couple of phone calls back and forth and I also documented the types of connectors on either end of my shrouds. (I’m keeping wire in the forestay securing my furler).

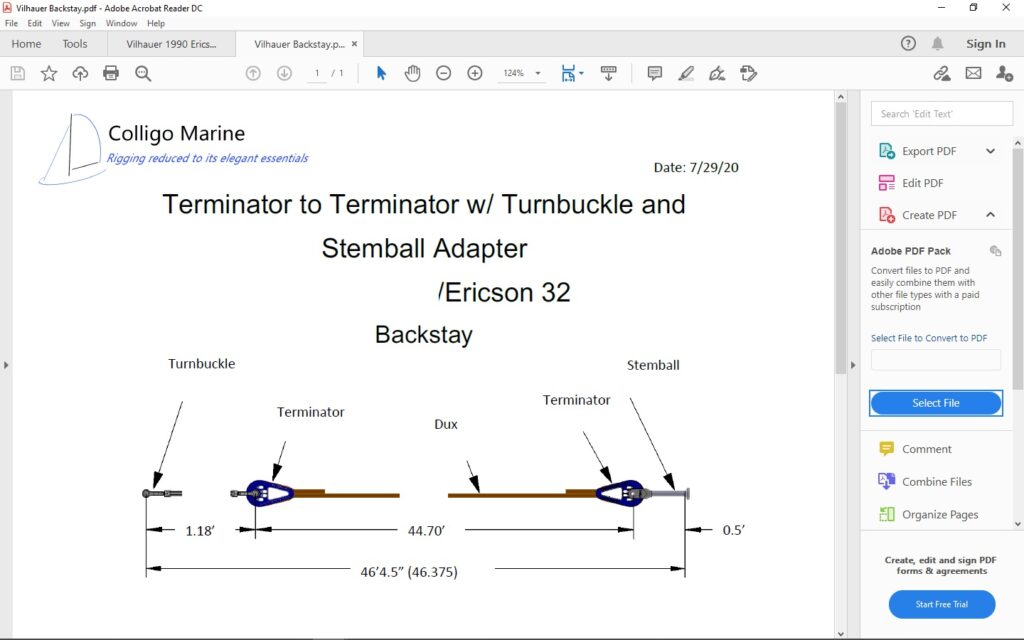

Franta takes all of the information the customer provides and puts those into engineering schematics with values from the order form. The customer receives these drawings back with another chance to sanity-check everything. The drawings look like this:

So far so good. Paid the money, got the order rolling.

At this point my boat was out of the water at the boatyard. My bottom paint job was complete along with my other hauled-out work, so the yard plopped my hull back in the water and left me sitting motor-boat style at their docks (i.e. with my mast still pulled). One delay has led to another with Colligo. First not the right rope on hand, now not the right stemballs.

So great, so awful is the woe of the recreational yachtsman who cannot obtain his obscure parts during a pandemic! #firstworldproblems

I’m waiting for the rigging to be finished at Colligo and shipped to me. Small, specialized parts from a small, specialized company with small, specialized suppliers. The wait has given me time to think through a couple more things, so I shouldn’t complain. I’m missing prime August sailing here in SF, but it’s probably my fault for scheduling a haul-out in the middle of the summer.

At some point they were going to start charging me at the boatyard for storing my boat while I waited for my owner-supplied parts. I decided yesterday to drive Sure Shot a couple hours over from Richmond to my home slip in Sausalito, so it would be closer for me to work on and to avoid any prohibitive charges from the boatyard.

Finally, I would add that the process of “owning” every measurement of my rigging has been a good one. Tex posted a good video on this note just this week. Before this process, the standing rigging was an abstraction to me: “those wires that hold up the mast.” I now better understand how everything works and hopefully this will help me make better/smarter/safer decisions. I hope I’m as self-satisfied once I get the lines and install them.