Never waste a crisis, right?

While my boat is hauled out to have the hull repaired, it seemed like an opportune time to determine the condition of my steering mechanisms and my rudder.

The quadrant is the only thing that holds the rudder in the boat. The quadrant grips the rudder stock and twists between the lower stuffing box and the upper bearing. It’s not clear to me if any prior owners have ever removed the quadrant or rudder for maintenance.

Phase 1: Disassembly

My first step was to remove the steering cables from the quadrant. The cables themselves carry no great tension, and I could pull them down ½”-¾” with my fingers. The cast-aluminum quadrant has experienced corrosion over 30 years.

The cables cross one another inside the pedestal to ensure the rudder turns the correct direction as directed by the wheel. This is important to remember when replacing the cables (thanks to Christian Williams for pointing this issue out).

The cables run from the helm through the pedestal to pulleys to eye bolts that are screwed into the quadrant. The connection was gritty with corrosion, and I had to tap the bolts out gently with a hammer to liberate them.

I could then pull the steering chain/cable out through the top of the steering pedestal. I had to remove the cable clamps in order to permit the cables to pass up and out past the idler pulleys. Unbolting the quadrant from the rudder stock was not an ‘easy’ process due to the amount of corrosion that had built up.

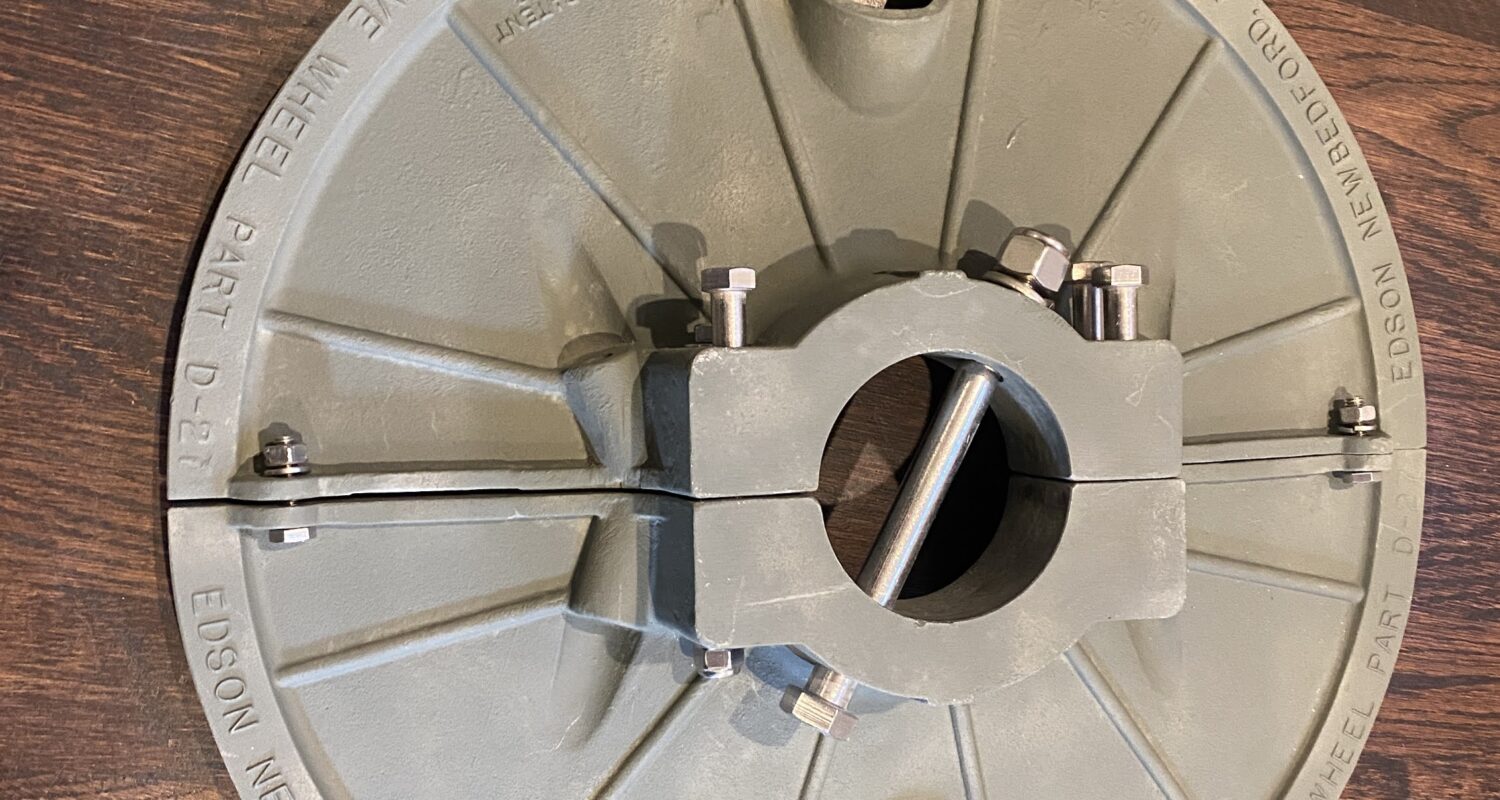

I have an Edson 800-8 quadrant, that consists of two semicircular halves bolted together. There are two small ¼” alignment bolts at the outside perimeter, four ⅜” bolts around the “collar” that help the part grip the rudder stock, and finally a ½” diameter ‘king pin’ bolt that traverses the diameter of the rudder stock. It is this ‘king pin’ bolt onto which the emergency tiller handle attaches.

The stainless steel bolts had become corroded into the aluminum quadrant. The four ⅜” bolts at the collar are threaded directly into the aluminum, and these were very reluctant to come out.

I used some heat to try to expand the aluminum..

I used a torque wrench connected to a 6” extension to the ratchet to be able to reach under the quadrant. This was awkward difficult work hanging torso-down into the cockpit locker. I unfortunately sheared off the head of one of the bolts with the shaft still corroded into the quadrant.

After a total of about four hours of grunting the bolts out, I was able to wedge a narrow pry bar in between the two halves of the quadrant, enough to lower the rudder from the bottom of the boat.

Rudder Lowering, Measurements

The rudder seems to be in excellent shape. No cracking apparent in the stock, no deformations in the surface. Well-sealed. This appears to be a different shape than a photo I have seen of the rudder on the 32-200’s close relative, the Ericson 32-3.

I took measurements for future reference. This diagram is now in the EricsonYachts.org resources section.

I brought the quadrant home for cleaning and further disassembly.

Scrub scrub with a brush and water. Scrub further with a wire bristle brush. The one bolt whose head I had sheared off in the removal process was a problem. The bolt shaft was lodged, connected to both halves. I eventually drilled out the bolt shaft to free the two sides.

Soak the two pieces of quadrant in vinegar overnight. Brush away a lot of corrosion.

I bought a tap to clean and re-form the corroded threads for the ⅜” bolts that grip the quadrant to the rudder stock.

I decided to replace all of the fasteners. Some had been damaged in the removal process and all were corroded somewhat. I found all of the right sizes at Central Hardware in San Francisco.

I washed the aluminum pieces, cleaned them with acetone and declared they were ready for paint.

A couple of light coats of Rust Oleum metal-etching primer to retard future corrosion, and we have it:

Next up: steering cable inspection and review, eventual re-assembly of rudder in the boat.