High Voltage

I headed out for a day sail this week and was motoring about 50 yards out of my slip when my remote radio mic on my helm began beeping at me and flashing a “HIGH VOLTAGE” warning. Having blown a fuse in a Standard Horizon head unit during my electronics upgrade, this seemed like a noteworthy alarm. I did exactly what Joshua Slocum or Bernard Moitessier would do in the same circumstances and I put my motor in neutral in the channel, whipped out my iPhone and googled, “Boat 12 volt High Voltage warning.” The first web page I found warned, “You better fix that or you will screw up your electronics. Probably your voltage regulator for your alternator.” Curses! I headed back to my slip.

Normally, without trickle charging, my batteries will hold about 12.8 volts. With the alternator running, the voltage normally increases to about 14.4. My radio high voltage warning was valid in that my dash meter showed 17.5 volts. Too high.

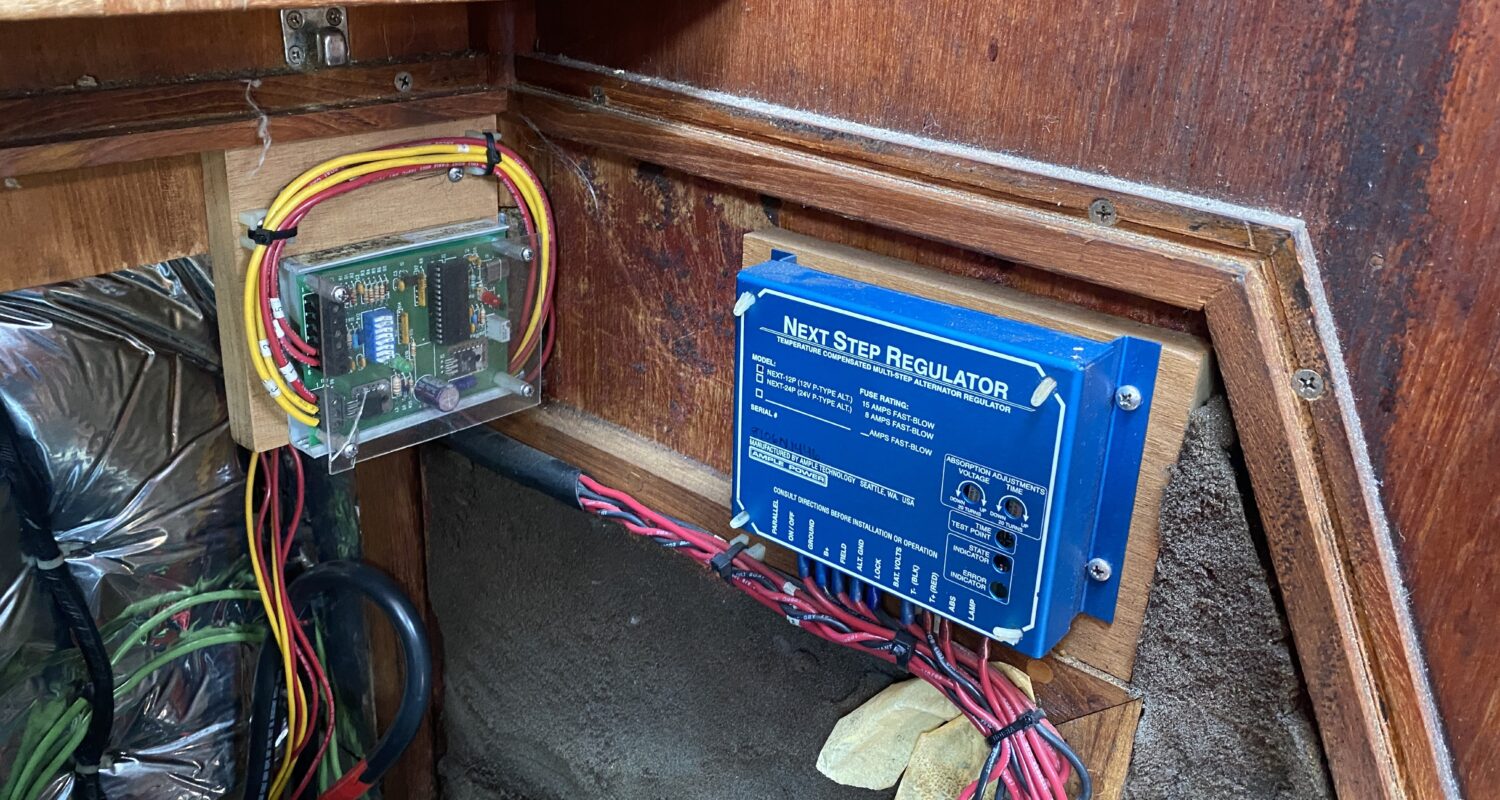

I’ve had some misgivings about my voltage regulator for some time. Not because it has performed badly. It just looks like a component that belongs in a 1980’s pizza restaurant PacMan arcade game. The other thing next to it is probably a flux capacitor from a DeLorean.

Curses again! Now I would have to figure out where all those wires go and what they do. I put the cover back on the engine bay and started to get up. I looked over at my battery bank switch.

I have two battery banks – bank 1 and bank 2. (I know, right?) The selector switch allows my boat to draw power from neither bank, bank 1, both banks, or bank 2. The instructions from the previous owner were to leave the selector to “both” all the time (charging, starting, and use) and go have a good time sailing.

Working in the quarterberth I had apparently bumped with my foot the selector from the ‘both’ setting and onto ‘bank 2’ This meant the trickle charger had only been charging bank 2, and with the engine running, all of the alternator’s efforts were devoted to bank 2. It was, like one of my former co-workers on a trip to Las Vegas, over-served.

This is not my best photographic work:

I switched it back to ‘Both’. I also checked on the amount of distilled water in my open cell bank (bank 1) in a locker under my forward V berth. These were low on water, so I topped them up. Cranked the engine back up, and back at the normal low 14’s while charging.

Moral of the story is to check the battery switch if you get an errant high voltage warning.

Grimey Balls

Cockpit scuppers are drains that ought to permit any water that enters the cockpit to drain out of the boat.

My boat lists to starboard and water accumulates on this side of the cockpit. Within my scupper there is a ball that floats and is intended to prevent backwash from waves into the cockpit. It sometimes clogs the flow of water out of the cockpit. I made a very serious film about this problem.

After checking with some other owners in the Ericson forum, no one else seemed to have any grimey balls on his/her boat. I decided I should try to remove my balls. It turns out that the cups cradling my balls were attached with 3M 5200 adhesive, making the retrieval of my balls nearly impossible. I decided that a good alternative was to scrub my balls as best as I could and not let them get too grimey. This may or may not solve my problem.

Bilge Cleanout

My Ericson 32-200 has a collection of five bilge compartments that are formed from low spots in the structural Triaxial Force Grid, which sits between the outer hull and the sole of the boat. I have several bilge pumps that can draw water out automatically, but inevitably a good amount is left in the bilge compartments.

I have tried several methods to remove the ‘last bit’ of water, including sponges and a turkey baster. Do you know what the best part is about getting water out of a bilge several tablespoons at a time with a sponge or a turkey baster? There is no best part. It’s a boring, inefficient way to spend time you could be sailing.

But gradually between rain and a weeping prop shaft packing gland, the water gets in. I decided to upgrade my technology and bought a plastic transfer pump. As I look back now for the link, I see I was thoroughly Jedi-mind-tricked into buying a “Koehler” pump when I thought I was buying a “Kohler” pump. (“Hey, it’s not copyright violation if we spell it differently and the careless Americans buy them anyway.”)

In any case, the pump worked pretty well. I extracted more water than I have been able (willing) to extract by other methods. Once I had the water out, it was much easier to scrub out some bilge nastiness from the keel bolts and the bilge walls.

Yanmar Cold Start

Sometimes it takes a few cranks to get my Yanmar 3GM30F going. From a Yanmar group on Facebook I learned about a technique to pre-lubricate the cylinders with the compression levers open. I made a short video about the process: