I wrote about my plans to ascend my mast with a newly-purchased mast-climber on my wire rope halyards.

The feedback I received was not to climb my wire-rope halyards, and instead to replace them with all-rope lines.

One choice would have been to locate a local reliable rigger to make some new ones for me. I hesitate to do this for a “small job” because to get any competent person in the SF bay area to drive to a location of your choice and put his car from drive into park costs about $150 to start. In addition to cost by doing this and job myself, I develop something I can describe (partly in truth) as competency.

I wanted proper halyards, with splices pre-made (I’m not willing to develop splicing competency at present). I found some at Defender. I ordered 7/16″ (11mm) nominal width lines. After others comments, I think I have wound up on the “thick” end of the spectrum, with many others at the 3/8″ 9/10mm width. I knew my clutches would grip 7/16″ lines well, having gone through the same process to run a new reefing line as part of my boom rehab.

This is what I got in the mail from Defender for $120 plus shipping. 110′ long, so right around a dollar/ft including the splice and shackle. Bright, supple, and strong (new ropes are sexy). The “headboard” shackles are robust and, for better or worse, cannot be removed from the splice except by destroying the fixed pin located midway up the shackle horseshoe.

One trick with putting up a new halyard is that one has zero control from the deck of the boat over what happens at the masthead sheave. Any knot tied to connect the old and new lines would jam, so getting it right the first time, and avoiding a jam at the top suggests some planning.

The other issue with my halyard (probably yours too) is that the splice eye at the sail end of the halyard would not slide through the sheave (pulley) at the top of the mast.

The halyard can effectively only be taken out in one direction, and then be replaced by reversing the direction pulled. This implies that one needs a tracer or helper rope that can run through the path of the halyard through the mast and be lowered enough such that the old halyard can be removed, the new one re-attached, and pulled in reverse order.

Another possibility would be to clip off the splice eye end of the halyard. Doing so would avoid the need for an “intermediate rope” but be destructively inelegant if the old-halyard-with-eye-splice has any residual value.

In either case, one needs to be able to connect the new halyard to either the old halyard or an intermediate rope without using a knot and in such a way that the connected lines will flow through the masthead. Here’s a how-to video to connect your old and new line with some sewn twine:

I wanted to keep my old halyards, so I had to contrive an ‘intermediate rope/tracer’ from two existing spare ropes. I went to West Marine and got a set of needles ($7) and some fancy sail repair twine ($20), to try to effect what the round faced man in the SailRite video was doing.

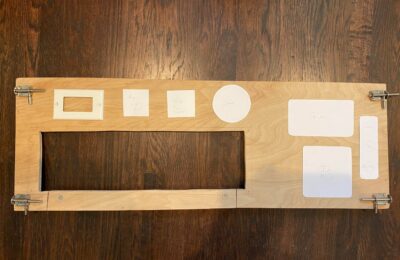

Here’s an ugly first try on my ‘tracer’ temporary line. Neither the red/white rope or the yellow nylon rope alone were long enough to go up the mast and back down, so I had to connect them:

Hide the loose twine threads with blue tape for sheave-flow:

Do the same thing to connect the mated line to the old halyard and pull it all the way out of the mast.

You can see the hooked needle I used in the following shot. West Marine was out of sailing palm needle pushers, or else I would have purchased one. A palm would have been unnecessary for this job. Needle-nosed pliers helped here and there, but mostly I could push the needle through by hand.

So, those are the simple steps:

1. Connect the tracer line to the old halyard.

2. Back the old halyard all the way out on to the deck.

3. Detach the old halyard from the tracer line.

4. Attach the tracer to the new halyard, pull it back through.

Repeat same steps for the jib halyard.

So far, the 7/16″ line flows nicely through the masthead sheaves etc.

Having a new supple rope is an improvement.

Everything worked. 90 minutes for the first, main halyard, 60 minutes for the jib, with 20 dedicated to unfurling, wrestling, lowering/raising, furling the jib in 10 knots in the slip.

Next up is actually climbing with the new lines.

Yes, I will use a separate climbing rope, and not let my climbing cams damage my new pretty halyards.